– No Park Gear On That 727 Torqueflite Transmission –

A while back, I scored a 383 big block from a ’69 Charger, complete with a 727 transmission still bolted on. The engine was a beast—I got to see and hear it roar before sealing the deal. So naturally, I assumed the transmission was in good shape too. No red flags, no second thoughts.

For about a year, both the engine and transmission sat in storage while I tackled other projects. But eventually, the day came—I was ready to drop that big block and tranny into my Fury. That’s when the reality hit me: the transmission had a problem… and I could only hope that it would be a simple fix…

THE BEGINNING:

– How It All Started –

Showing That 727 All Noice And Shiny

Black Primer Coat

First, I gave the entire transmission a thorough cleaning with brake cleaner to prep it for a fresh coat of black primer. After carefully taping off all the areas I didn’t want to touch, I sprayed the primer and let it dry. Once it was set, I hit the transmission with a coat of Duplicolor Hemi-Orange to perfectly match that bold orange big block!

Now thats one sharp looking tranny right there!

NEXT UP:

– Installing a B&M Megashifter –

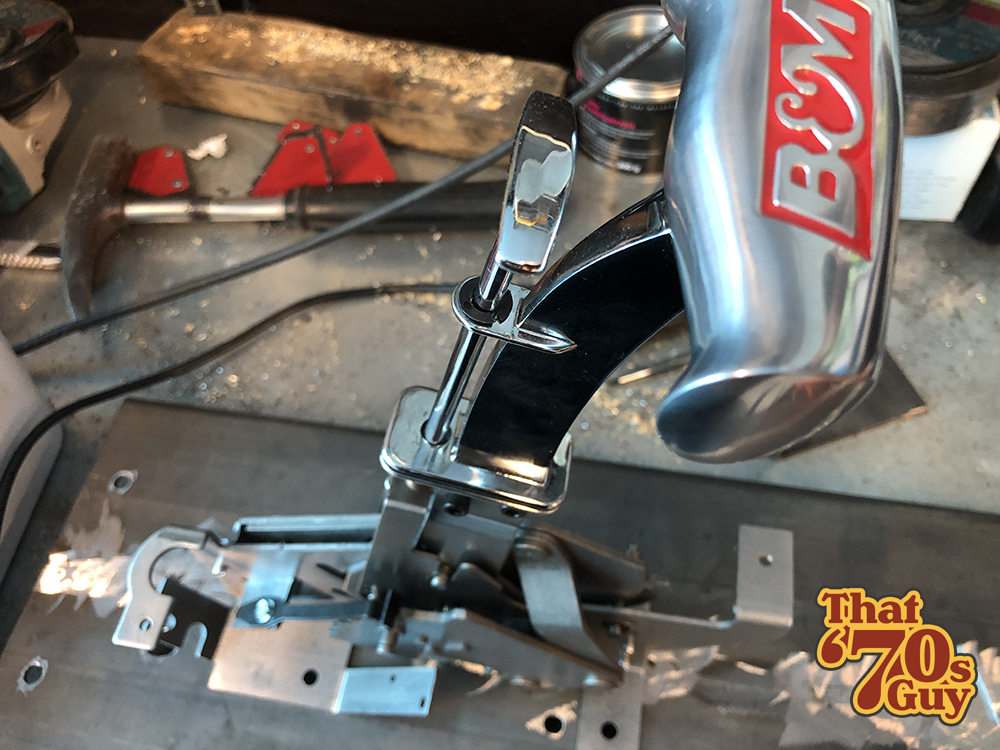

I’ve always had my eye on the B&M Megashifter, so I finally ordered one from Summit Racing. The installation was pretty straightforward: it mounts with four bolts through the transmission tunnel and operates via a cable attached to a special bracket on the transmission.

Here is the Megashifter I’ve bought from Summit racing without its housing

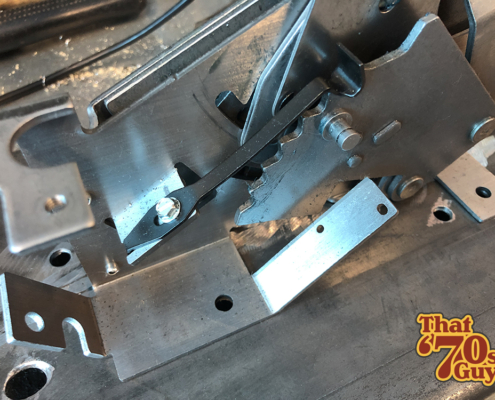

After drilling the necessary holes and creating an opening for the cable, everything seemed to be in place. But once I started shifting, I noticed some wobble—the shifter felt loose when moving up and down, and the whole unit had a bit of side-to-side play. Turns out, those four bolts weren’t enough to keep things completely secure.

To fix it, I went ahead and welded the sides of the shifter to the transmission tunnel. That did the trick for sure and if you are installing one of those, and your transmission tunnel is round AF, I recommend givin’ it a few welds too.

Still had no clue for the problem that was coming tho…

A Close Up Of the Installation Holes

I Cut a Hole For The Shifter Cable To Go Through

Bolted Down And Welded For Extra Strenght

NEXT UP:

– HOUSTON, WE HAVE A PROBLEM –

That triangle shape adapter was provided by B&M

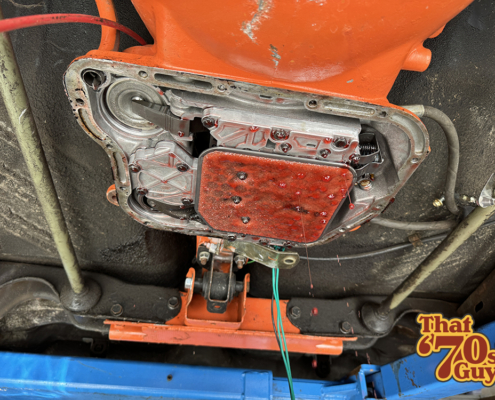

I threaded the B&M shifter cable through the floor and connected it to the B&M adapter on the transmission. It was a simple bolt-on job, using two existing oil pan bolts on the tranny. But when I started adjusting the gears, starting with the first gear, I noticed something odd—it only clicked four times instead of five. At first, I thought I’d miscounted, so I tried again. Then reality kicked in: I had no parking gear!

Removed All Shifter Linkages And Dropped The Pan

Man, It Kept On Leaking For Days!

What The Hell Is That Ball!

NEXT UP:

– IT WASNT AS BAD AS IT LOOKED –

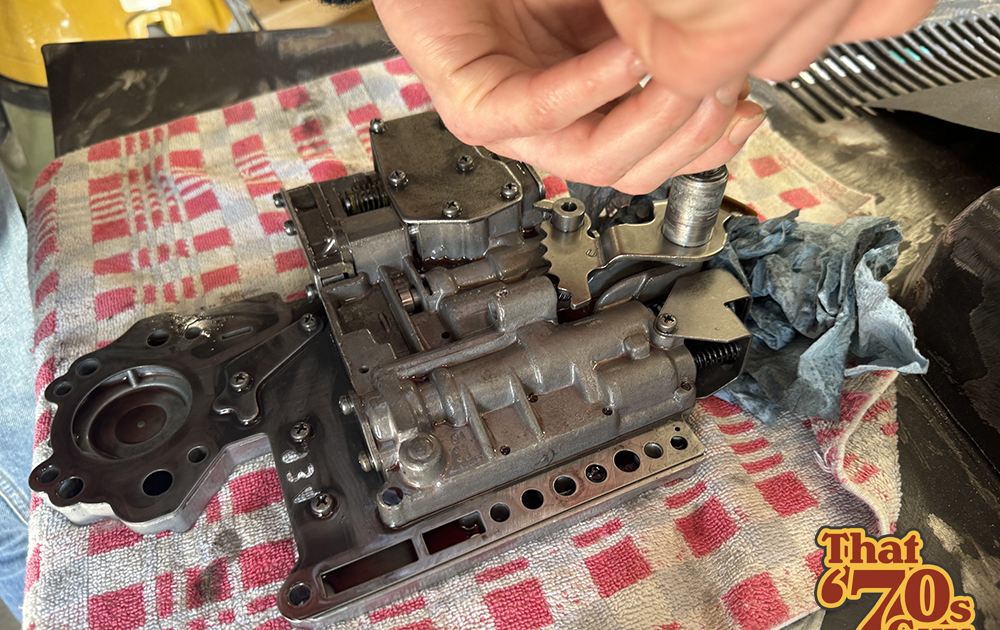

Watching that metal ball bounce around in the oil pan was a sight that instantly spelled trouble in my mind. My first thought? It had to be one of those balls from the valve body, and that meant serious problems ahead. But, to my relief, it turned out to be the ball from the shifter mechanism—it had simply slipped out of the shaft.

You see those teeth? There should be a ball between them.

The Valve Body Was Just Fine.

All Bolts That We Removed From Oilpan to Valve Body

Now that we’ve identified the problem, the real question is: what caused it? We can only speculate. Perhaps something bumped the gear selector while it was in storage or during transport, causing it to tilt just enough for the spring-loaded ball to pop out. With no bearing on the gear selector, this seems like a plausible explanation, but again, it’s just guessing. If you have any clue, please reply in the comments.

The inside of the gearbox with the valvebody removed

Setting the valvebody into place

Installing a new filter

Now with the ball back in position, it was time to put all parts back into place. We installed the valvebody back into the gearbox housing, making sure the parking brake rod was aligned, installed a new filter and closed up the oilpan.

We torqued everything to spec:

- Valvebody to case screws: 100 in/lb

- Filter to valvebody: 35 inch/lbs (that is just hand tight with a screwdriver)

- Oilpan to gearbox: 12.5 ft/lb (or when using a cork gasket, as soon as you see the gasket push out…STOP)

And closing up the oilpan

The Big Moment! Do We Have All Gears?

YES WE DO!

So it wasnt a big deal after all. The transmission is working like it should and it shifts all the way from 1 till park. Now we can install the B&M shifter and get it to work. Thanx for reading y’all!

Leave a Reply

Want to join the discussion?Feel free to contribute!